Vehicle logistics presents significant challenges that can disrupt your supply chain and impact your bottom line. Inefficiencies in rail car maintenance operations, safety and compliance issues, a lack of control over shipping schedules and escalating operational costs are common hurdles that may hinder the automotive industry’s growth and efficiency.

FLEXRail offers robust automotive logistics solutions tailored to overcome these hurdles. With over four decades of experience, FLEXRail transforms these common logistical barriers into strategic advantages, optimizing your global logistics supply chain with a strong focus on consolidation and enhancing operational success. This ensures your automotive logistics — production logistics and finished vehicle logistics (FVL) — are streamlined and adaptive, leading to significant cost savings.

Challenge 1: Inefficient Rail Operations

A large-scale automotive manufacturer relies on timely deliveries of critical engine components sourced from various suppliers. Any inefficiency in rail car maintenance operations, such as outdated switching services or poor railcar management, can lead to significant bottlenecks.

For example, if a railcar that is supposed to deliver steel to the engine manufacturing plant is delayed due to inefficient scheduling or mismanagement, the entire production line can halt. This causes manufacturing delays and forces the automobile manufacturer to incur higher costs through expedited shipment of production parts or even temporary shutdowns.

Every hour a shipment is delayed compounds these costs, affecting overall business profitability and operational efficiency.

FLEXRail’s Automotive Logistics Solutions

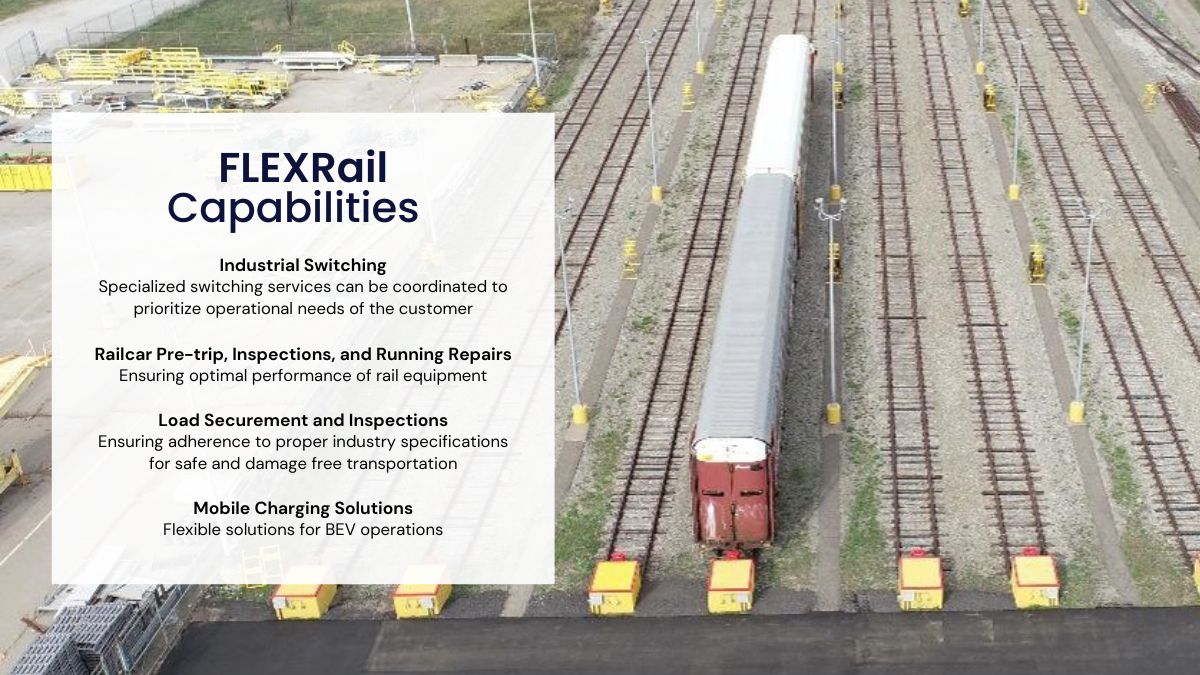

Customized Industrial Switching

FLEXRail recognizes that one size does not fit all in logistics. We offer customized switching services tailored to align with your specific operational priorities. Whether you need prioritized loading and unloading or specific sequencing of railcar movement, FLEXRail designs these services to enhance the fluidity and efficiency of your operations.

We also custom-design railcars to enhance safety and streamline the transport of vehicles.

Partnering with Precision Vehicles Logistics ensures every vehicle is perfectly loaded and ready for transit.

This tailored approach ensures that logistics operations are streamlined, significantly reducing bottlenecks and improving overall throughput.

Reliable Railcar Management

To further support efficient operations, FLEXRail implements a robust railcar management system. This includes comprehensive pre-trip inspections and ongoing maintenance schedules, ensuring that each railcar is in optimal condition before and after operations.

Such diligence minimizes the likelihood of unexpected breakdowns and maintenance issues, which are often costly and disruptive. By keeping railcars in peak condition, FLEXRail helps maintain consistent delivery schedules, reduce downtime and ensure that your products reach their destination on time.

Challenge 2: Safety and Compliance Concerns

Challenge 2: Safety and Compliance Concerns

Safety standards and regulatory compliance present a significant challenge, particularly for industries transporting hazardous materials or fragile goods.

The Cooperative Research for Hazardous Materials Transportation report discusses the critical role of technological innovations in improving safety protocols and tracking systems for hazardous materials transportation. Integrating new technologies like real-time tracking and advanced containment systems could significantly reduce risks.

Regulatory Compliance

Transporting lithium batteries requires compliance with complex regulations that vary by country and region. These include guidelines for handling, packaging and labeling set by agencies such as the Department of Transportation (DOT).

Ensuring the safety of lithium-ion batteries during transit involves rigorous packaging procedures, including insulating materials and robust containment systems, to mitigate the risks of short circuits.

Training and Equipment

Logistical staff must be trained in handling hazardous materials and equipped with the necessary tools and knowledge to manage the unique challenges lithium-ion batteries pose.

Choosing a logistics partner that safely transports hazardous materials is crucial for industries relying heavily on these batteries, such as automotive manufacturers. This ensures the protection of high-value cargo and safeguards the company’s reputation by minimizing risks and enhancing reliability in their automotive logistics and supply chain operations.

FLEXRail’s Automotive Logistics Solutions

Enhanced Load Securement

FLEXRail adopts the most stringent industry standards for packaging hazardous materials, utilizing state-of-the-art insulating materials and robust containment systems to prevent damage or mishandling during transit. This ensures safety and aligns with the specific requirements of regulatory bodies like the Department of Transportation (DOT).

Each shipment of lithium-ion batteries is treated with tailored safety protocols designed to address the unique risks associated with these components. These include specialized fixtures that prevent movement within the railcars and advanced monitoring systems that alert logistic teams to potential issues in real time.

Comprehensive Training Programs

FLEXRail ensures that all personnel handling, transporting and managing lithium-ion batteries are thoroughly trained to comply with the latest safety standards. This training is regularly updated to reflect the newest regulations and best practices, ensuring all team members are proficient in the safest and most effective handling procedures.

In addition to training, we equip our staff with the tools and technology to safely manage the logistics of lithium-ion batteries. This includes personal protective equipment, emergency response kits and specialized tools for safely securing and monitoring the condition of the batteries during transport.

Download our whitepaper to learn more about our safety procedures.

Innovative Mobility Solutions

FLEXRail incorporated innovative mobile charging stations, recognizing the growing demand for electric vehicles. These stations ensure that electric vehicles and battery-powered equipment are fully charged and operationally ready upon delivery.

These mobile charging solutions are integrated with comprehensive safety systems designed to manage the specific risks of charging electric batteries. These systems include features that prevent overcharging and monitor battery health during transit.

This commitment to safety, combined with advanced technological integration, positions FLEXRail as a leader in the logistics of high-value, high-risk goods. It ensures we meet the evolving needs of industries like automotive manufacturing while maintaining strict compliance with global safety standards.

Challenge 3: Lack of Control and Flexibility

Challenge 3: Lack of Control and Flexibility

Many businesses find that the rigidity of traditional rail services does not align with the dynamic needs of modern supply chains. This misalignment is critical for industries that require high levels of precision and adaptability in their logistics operations, such as automotive manufacturing.

According to Supply Chain Brain, “Automotive supply chains are made up of multiple tiers of suppliers, manufacturers, distributors and service providers, spread around the world. A typical motor vehicle can contain anything between 15,000 and 25,000 parts. That’s a lot of material to bring together and provide integrity for the final product.”

Inflexible Schedules, Lack of Real-Time Control and Limited Routing Options

Traditional rail services often have fixed schedules and limited routes, which can fail to accommodate the fluctuating supply and demand dynamics.

An automotive manufacturer might experience a sudden increase in demand for a particular model due to a successful marketing campaign or a variety of other reasons. The manufacturer may not meet the increased demand if the rail service cannot swiftly scale up the transport to and from the regional distribution center of necessary components on the basis of available truckload options, due to its inflexible schedules and routing.

This misalignment can lead to potential sales losses, customer dissatisfaction and disruptions, underscoring the critical need for more adaptable transportation management system (TMS) solutions in such dynamic market conditions.

Without real-time monitoring and adjustment of freight shipments, businesses face difficulties managing their supply chains effectively. The inability to respond swiftly to logistical challenges, such as rerouting shipments around a disrupted rail line, can exacerbate delays and inflate costs.

FLEXRail’s Automotive Logistics Solutions

Tailored Switching Services and Enhanced Railcar Management

FLEXRail offers specialized industrial switching services that can be customized to meet your specific operational needs. This service ensures that resources are prioritized appropriately, enhancing rail operations’ flexibility to adapt quickly to changes in production schedules or market demands.

With a robust approach to railcar pre-trip inspections, maintenance and repairs, FLEXRail ensures that the railcars are always in optimal condition and ready for deployment without delays. This reliability in equipment management minimizes downtime and contributes to a more controlled and flexible logistics operation for your business during tight production schedules.

Mobile Charging Solutions and BEV Support

Due to the increasing adoption of battery electric vehicles (BEVs) and the specific challenges associated with electrification and transporting such high-value and sensitive products, FLEXRail has integrated mobile charging solutions. These cater to the operational needs of transporting BEVs and ensure that these vehicles are handled with the utmost care and ready for immediate use upon delivery, aligning with sustainability goals and operational efficiency.

Challenge 4: High Operational Costs

Challenge 4: High Operational Costs

Logistics costs can quickly escalate due to inefficient fleet management, underutilized assets and the frequent need for costly interventions. Unexpected equipment failures and inefficient operational practices exacerbate these financial burdens, increasing direct costs and affecting overall supply chain efficacy.

FLEXRail’s Automotive Logistics Solutions

Enhanced On-Site Support and Comprehensive Fleet Solutions

FLEXRail’s on-site support services are designed to streamline operations and reduce the need for expensive logistical interventions. By providing faster recovery times and resolving issues promptly, FLEXRail minimizes downtime and maximizes operational continuity. This proactive approach significantly reduces the overall costs associated with rail logistics, from decreased downtime to less frequent need for emergency repairs.

Understanding the importance of cost-efficiency, FLEXRail offers solutions designed to maximize fleet uptime and productivity. This includes leasing equipment with local service plans that ensure operational readiness and utilizing a non-union labor force to keep labor costs competitive while maintaining high service standards. These measures reduce operational costs and improve fleet utilization, ensuring that every asset contributes optimally to your supply chain.

How do automotive logistics solutions optimize supply chain processes?

How do automotive logistics solutions optimize supply chain processes?

Automotive supply chain solutions enhance visibility and traceability, reduce lead times and improve inventory management. By streamlining operations, they minimize costs, increase efficiency and ensure the delivery of vehicle parts, spare parts and products throughout the supply chain at the right time.

FLEXRail Transforms Your Logistics Challenges into Strategic Advantages

FLEXRail, a premier automotive logistics provider, delivers customized automotive logistics solutions to meet unique operational demands. With over four decades of expertise, our advanced industrial switching services and comprehensive railcar management are tailored to ensure flexibility and reliability in your supply chain.

We believe in partnership, going beyond expectations to ensure your success. The FLEXRail difference lies in our unwavering attention to detail, willingness to go the extra mile at our own cost and dedication to creating premier facilities tailored to our customers’ needs.

Our commitment extends beyond conventional logistics with innovative solutions like mobile charging stations for battery electric vehicles (BEVs), reflecting our support for sustainable transportation solutions.

Our automotive logistics specialists ensure a customer-centric approach throughout transportation, particularly during critical first and last-mile phases. This holistic approach enhances control over shipments and provides faster recovery times. It also bolsters your company’s reputation by aligning with industry-leading safety and compliance standards.

Contact FLEXRail today to transform your logistics challenges into strategic advantages. Let us tailor an automotive logistics solution that propels your business forward with enhanced efficiency and reliability.

0 Comments