The rapidly changing automobile industry requires creative and flexible rail logistics solutions. Advanced rail technology leads this transformation, offering essential tools to improve operational efficiency, ensure safety and promote environmental sustainability.

As companies work to perfect their supply chains, rail technology provides groundbreaking opportunities that could dramatically change freight transport worldwide.

FLEXRail, as a leader in the field, enhances efficiency, safety and sustainability in freight transportation. Explore our advanced solutions and see how we’re setting new standards in the industry.

Challenges in Rail Logistics

Global supply chains are experiencing significant transformations, presenting multiple challenges for rail logistics:

- Demand for Efficiency and Resilience

With increasing global disruptions, such as economic shifts and pandemics, rail systems have never been more important in providing reliable and efficient transportation solutions. These systems are crucial in maintaining continuous operations despite external uncertainties.

The United States Department of Transportation notes that “freight and logistics infrastructure needs significant improvements due to deterioration from historic disinvestment.”

This includes upgrading physical infrastructure to withstand ongoing wear and tear and enhancing climate resilience to address challenges such as sea-level rise, storm surges and other extreme weather events that could disrupt operations.

- Complex Supply Chain Management

The growing complexity of managing supply chains, fueled by technological advancements, regulatory changes and evolving business strategies, burdens rail logistics.

Rail systems must manage these complexities while ensuring seamless goods movement across extensive networks.

- Enhanced Tracking and Security Needs

The modern supply chain’s dependency on timely and secure deliveries demands advanced tracking and robust security measures in finished vehicle logistics. Operators must implement comprehensive monitoring systems that meet stringent security requirements.

- Faster Turnaround Times Required

Today’s fast-paced business environment demands quicker logistics responses. Rail systems are pressured to accelerate operations, reduce transit times and enhance delivery reliability to keep pace with market expectations.

- Adaptability to Market Variability

Market demand and trade patterns are increasingly volatile, requiring rail systems to be highly adaptable. They must efficiently manage fluctuations in cargo volumes and dynamically adjust operations to meet diverse and changing industry needs.

These challenges underscore the growing pressures on rail logistics as they align with the demands of global supply chains. Each aspect highlights key areas where rail systems must excel to navigate and thrive amidst evolving economic and logistical trends

How is rail technology improving safety and efficiency in transportation?

Rail technology enhances safety and fuel efficiency through innovations like predictive maintenance, autonomous technology, real-time monitoring systems and mobile apps incorporated into locomotives that proactively detect flaws. These advancements help prevent accidents and collisions, reduce downtime, optimize routes and improve overall operational performance in the rail industry.

Comprehensive Enhancements in Rail Logistics

FLEXRail is committed to excellence in rail logistics, incorporating advanced technologies and systems to enhance transport operations’ safety, efficiency and sustainability.

Here’s how FLEXRail is setting new standards in the industry:

Safety and Quality Assurance Protocols

We uphold the highest safety and quality standards through rigorous monthly inspections, critical for monitoring on-site fuel usage and assessing equipment conditions.

These inspections ensure strict adherence to safety protocols across all operations, particularly those involving sensitive automotive components. This meticulous attention to detail helps prevent damage and maintain the integrity of transported goods.

Predictive Maintenance and Advanced Technologies

FLEXRail utilizes predictive maintenance technologies, leveraging data analytics and sensors to anticipate and address maintenance needs before issues arise.

This proactive strategy not only prevents unexpected downtime but also extends the lifespan of rail equipment.

Additionally, we integrate advanced logistics technologies, such as real-time monitoring systems and predictive tools, to mitigate disruptions and maintain precision in transload and multimodal operations.

These systems ensure that automotive components and finished vehicles are transported safely and in optimal condition.

Electrification and Advanced Monitoring

Electrification and Advanced Monitoring

Electrification and AUTOChargit Mobile UTV systems illustrate FLEXRail’s efforts to reduce reliance on fossil fuels and promote a cleaner, more sustainable transportation network.

Implementing zero-idling policies, energy-efficient operations and electrification underscore FLEXRail’s commitment to environmental sustainability.

FLEXRail also employs artificial intelligence-driven sensors and smart track monitoring technologies to enhance track maintenance. This approach allows rail operators to minimize downtime while maximizing operational uptime, significantly boosting overall logistics efficiency.

Using these advanced technologies in railway systems enhances operational reliability and supports seamless integration with other corporate operations, improving adaptability and efficiency across the supply chain.

Impact on Rail Network Sustainability

FLEXRail leverages automation, advanced algorithms, data collection and smart sensors to optimize rail operations, minimize human error and ensure the safe handling of high-value goods. These improvements meet stringent modern logistics requirements for safety and efficiency.

The environmental impact is also significant. The Association of American Railroads states, “Moving freight by rail instead of truck lowers GHG emissions by up to 75%.” FLEXRail’s investments in fuel-efficient technologies and automated systems further reduce emissions, emphasizing their commitment to sustainability.

These advancements demonstrate FLEXRail’s role in pushing beyond traditional expectations, setting new standards for the future of rail logistics and sustainable transport.

Advanced Rail Yard Management Systems

Advanced Rail Yard Management Systems

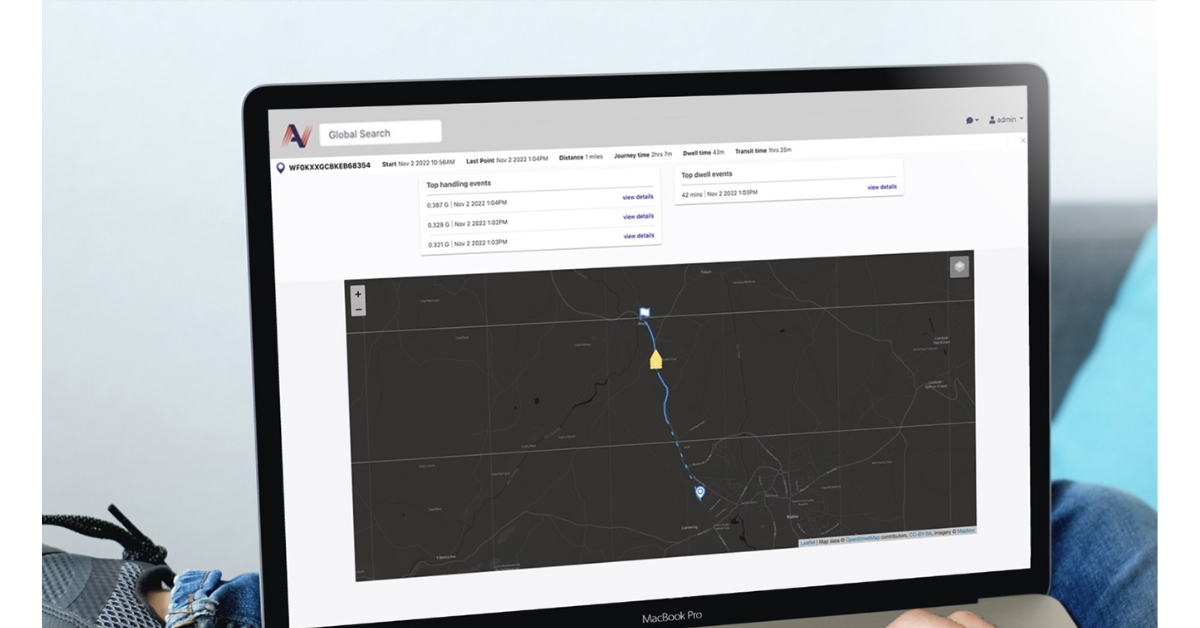

FLEXRail’s commitment to technological innovation is evident in its advanced Yard Management Systems (YMS), which are engineered with Internet of Things (IoT) technology and real-time data analytics.

These systems are tailored to meet the complex demands of rail logistics, providing essential benefits in managing assets, enhancing security and improving operational efficiency.

Real-Time Visibility and Operational Control

Key Benefits: FLEXRail’s YMS offers unparalleled real-time visibility, allowing logistics managers to track containers, pallets and railcars.

This capability is crucial for efficiently managing rail transport logistics. It enables FLEXRail to streamline operations by quickly locating and mobilizing assets.

This high level of control and visibility directly reduces operational delays and enhances throughput, effectively addressing common logistical hurdles such as misplacement and scheduling conflicts.

Proactive Delay Minimization

Key Benefits: FLEXRail’s YMS utilizes real-time data to facilitate rapid operational adjustments, minimize delays and enhance the responsiveness of rail operations.

Coordinating various activities — from train arrivals to cargo loading — is critical in rail logistics. FLEXRail’s ability to swiftly adapt to real-time changes helps prevent bottlenecks and optimizes the flow of operations, thereby improving overall efficiency and reducing the costs associated with delays.

Enhanced Security Measures

Key Benefits: The YMS enhances yard security through continuous monitoring and automated alerts, safeguarding against unauthorized access and potential security breaches.

This advanced security framework ensures that all freight, especially high-value or sensitive cargo, is securely managed both in transit and within the yard.

By protecting assets against theft and damage, FLEXRail safeguards shipment integrity and reinforces trust with clients and stakeholders focused on cargo safety.

Dynamic Scheduling Efficiency

Key Benefits: Dynamic scheduling enabled by YMS allows FLEXRail to maintain flexible operational timelines and adjust to changes as they occur.

The dynamic nature of rail logistics demands flexibility in scheduling to accommodate unexpected shifts in operational demands.

FLEXRail uses YMS to adapt schedules in real time, ensuring efficient resource allocation. This significantly reduces wasted time and resources while enhancing service delivery reliability.

By implementing these cutting-edge rail car management systems, FLEXRail improves the efficiency and security of its operations and ensures that its premier rail services remain competitive and responsive to the industry’s evolving needs.

Each component of the YMS is strategically designed to tackle specific rail logistics challenges, making FLEXRail’s operations more resilient and adaptable to the ever-changing complexities of modern freight transport.

The Pivotal Role of FLEXRail’s Advanced Rail Technology

Advanced railway technology transcends mere logistical improvements for sectors such as automobile manufacturing — it fundamentally reshapes them.

This technology heralds a future where transportation is quicker, more secure, environmentally responsible and seamlessly aligned with the strategic objectives of forward-thinking enterprises.

As we look ahead, rail technology will remain instrumental in shaping the logistics landscape, driving unparalleled advancements in efficiency and innovation at every turn.

Explore how FLEXRail is leading the transformation of rail logistics with its state-of-the-art technology and groundbreaking solutions.

Contact us to learn more about our initiatives, which are driving toward a more efficient and sustainable future in transportation.

0 Comments